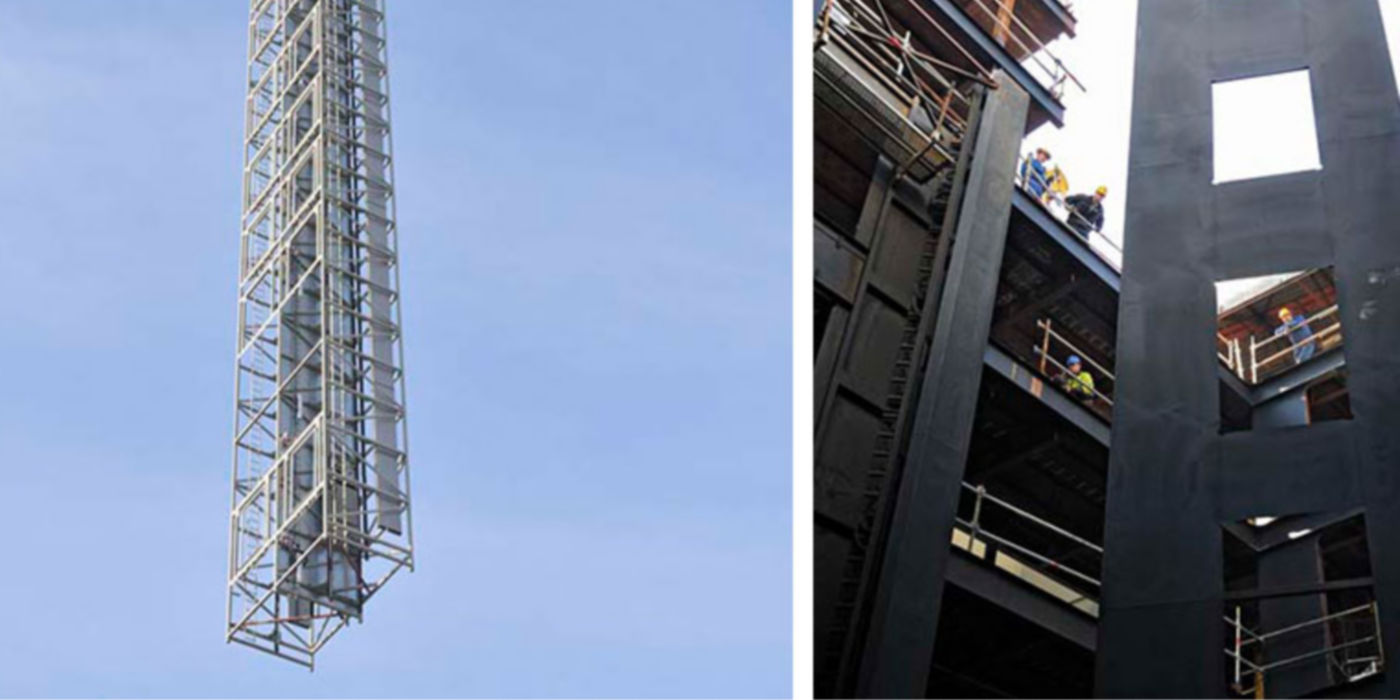

From the bustling city street it looks like yet another construction site: cars zip past colorful temporary hoarding, and a red double-decker bus tells us we’re in central London. A crane is offloading a large, white-wrapped package from a truck. But this is a little piece of construction history in the making: the package is a ready-made elevator shaft that’s about to be installed straight into the building, in a process that will take hours instead of the usual weeks.

Pressure to build faster and safer has long weighed on the construction industry. Over half the world’s population live in urban areas, and this is expected to rise to 85 percent by 2100. Add to this the need to ensure urban livability into the future, while minimizing impacts on the environment, resources and biodiversity. It’s easy to see why modular construction is on the rise, since it helps provide a solution to many of these challenges.

What is modular construction?

Modular construction means that elements of a building are constructed off-site in a controlled factory environment and installed directly into the build. There are many ways to approach modularity, from single elements that can be clipped together using standardized connections to fully kitted out 3-D volumetric units. The benefits start at ensuring a safer and more controlled work environment and extend through just about every process – all the way to the bottom line.

“Some form of modularity has been adapted strongly, especially in certain portions of the industry,” explains Amy Chen, Chief Innovation Officer at KONE. “There are strong motivations. Modular construction in real-estate alone looks set to achieve a market value of $130 billion in Europe and the US by 2030, with potential for 14.4 trillion globally by 2030.”

Chen also cites a 2019 McKinsey report which found that recent modular projects are consistently accelerating project timelines by 20 to 50 percent. “For KONE, this means we are constantly looking at how we can help our customers in this building phase to build faster, more efficiently, using less materials and less energy,” says Chen.

Proof of concept at King’s Cross: S5

KONE put these ambitions to work in 2020 at S5 in King’s Cross London, partnering with Laing O’Rourke to prove that the modular concept could extend also to elevators. Developing and advancing a solution that was originally utilized on cruise ships around a decade earlier, KONE was able to offer crucial benefits for the construction of new real-estate.

“By spring 2020 we had successfully designed a working system, delivering two prototypes, both of which were a roaring success. They proved that the concept worked and that a lift could be modularized in the way that we’d designed,” says Sam Ward, Laing O’Rourke’s Programme Leader, Technology & Innovation Group.

Workers on site don’t have to deal with the usual volume of deliveries or the proliferation of exclusion zones as the shafts are installed. This is because volumetric frames are fabricated off-site then assembled, wrapped, protected and stored, ready to be delivered on site.

“One of the major benefits of the modular system is that it encourages a safer working environment for the fitters,” Ward adds. “We move work from a relatively confined dark, damp space on site to a controlled factory environment. Also there is only one delivery instead of multiple deliveries with multiple small components.”

Lifting the module from the back of the truck and into the shaft takes about 90 minutes. The rule of thumb for installation used to be one week per floor, so being able to install an entire three-story module in an hour and a half is transformative for the industry. Furthermore, the water tightness and weather tightness achieved from this gives customers project certainty from much earlier on.

Workers themselves report numerous benefits, including the reduced need for storage space, a reduction in both working at height and manual labor, and notably less on-site clutter, dust and noise.

How modularity supports more inclusive and accessible urban living

While both productivity and safety are at the heart of the trend for modular construction, it’s also interesting to see how it extends into the overall design and functionality of public spaces. As well as streamlining the building phase, a modular approach to construction supports the flexible usage of a building, allowing elements to be easily replaced, repurposed or retrofitted as usage changes. Future-proofing a building in this manner is both environmental and financially more sustainable.

It’s an approach that KONE has put to the test in the city of Shanghai, where the municipality introduced an ordinance requiring every four-story building to be retrofitted with an elevator, also addressing the needs of an ageing population. The majority of tenants were elderly or people with disabilities, so voice interfaces had to be installed in the elevators, which also had to be fully accessible, with integrated applications for the visually impaired.

“The project in China is about accessibility, making urban space more livable and doing so quickly and with minimal disruption to tenants,” explains Chen. “When modularity allows us to radically change the accessibility of a building in a week, instead of a month, it helps people maintain self-sufficiency.”

Furthermore, at a human level, modularity can make change not only less physically inconvenient, but also less emotionally daunting. By allowing a building to adapt to changing needs throughout our lifetimes, modular design offers limitless potential for aging in place, or perhaps even growing a family without relocating.

“We are not only an elevator company but a people flow company. Our mission centers on how we can help people flow inside and around to make spaces more humanized,” says Chen, encapsulating a philosophy that values both process and end result.

Building the cities of the future together

Globally, and across every sector, we’re seeking a more livable urban future. Beyond the many practical benefits, the trend towards modular construction represents the evolution of the industry into a more collaborative and innovative force – and that’s inspiring.

“The beauty of building these applications not as disparate, separate applications but building them on top of resilient, scalable, open infrastructure is that we could implement very similar solutions all over the world,” said KONE’s CTO Maciej Kranz, speaking at the Millennium Innovation Forum 2022. He also highlights the need for industry, government and academia to work together, using technology to create better human experiences.

“Urban and natural, convenience and community do not have to be mutually exclusive. And modular construction plays a key role in accomplishing such a balance,” he concludes.